Products

Self-inflated Gas Bag

heavy duty SANWEI Gas Bag , Apply for Open Pit and Underground Mines

- AIR DECK SOLUTION

- MODELS AND SPECIFICATION

- APPLICATION

- INSTALLATION

-

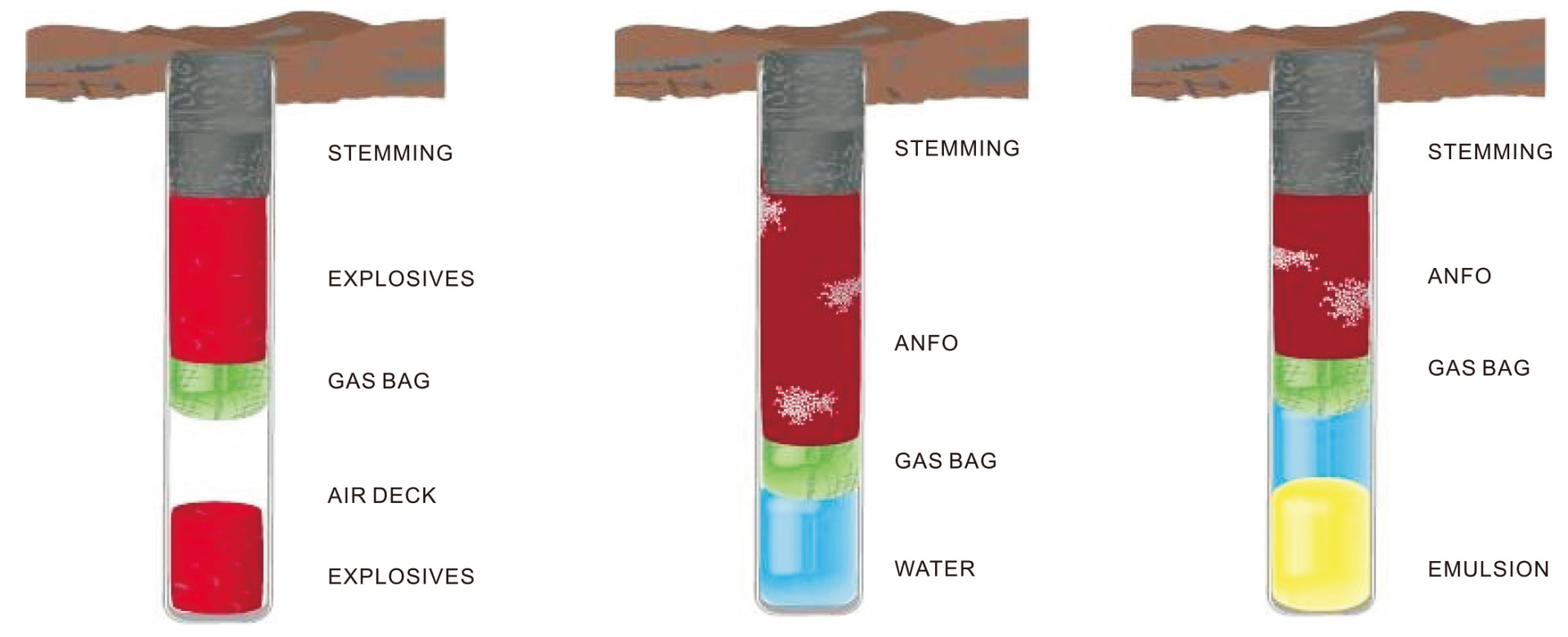

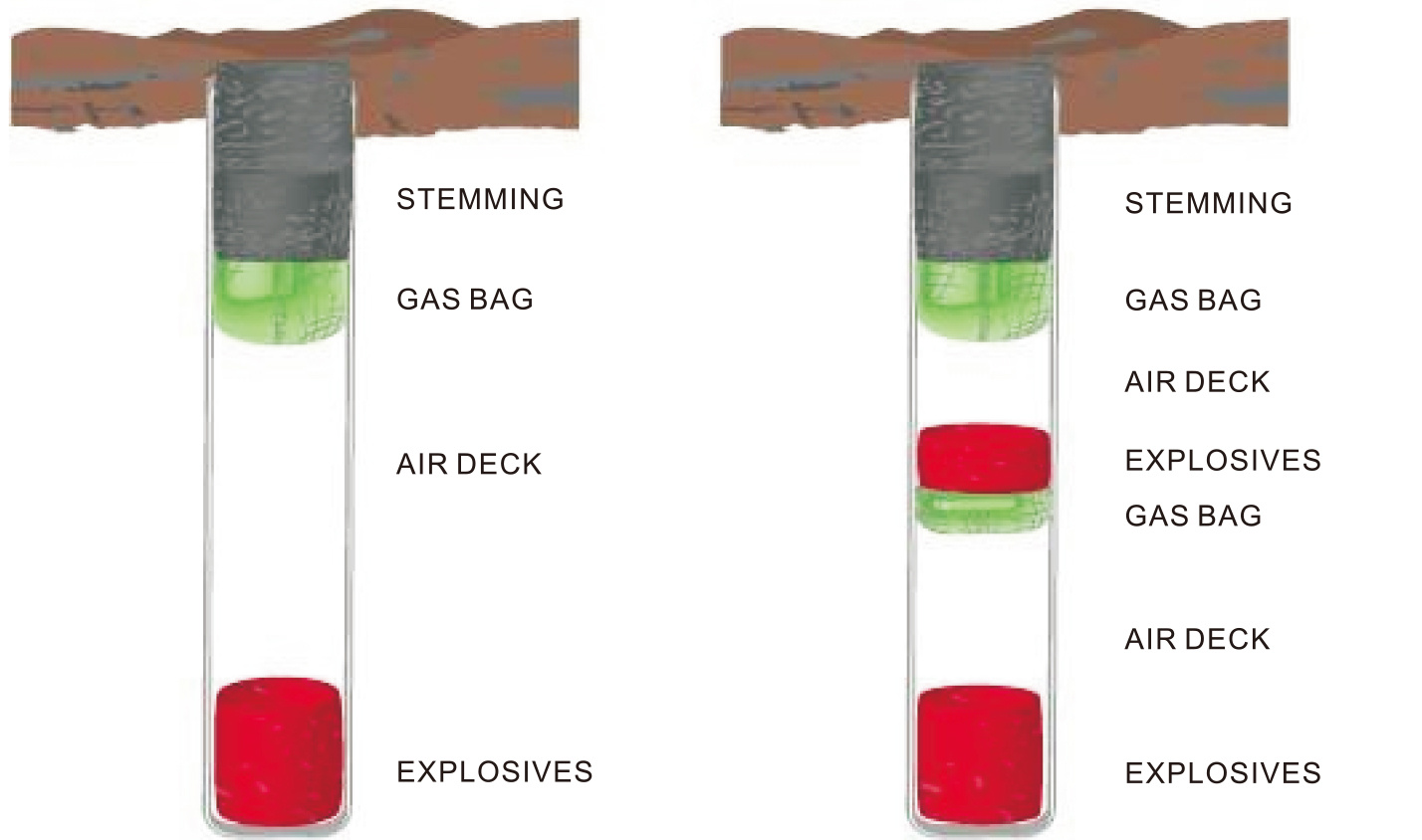

Background of Air Decks

In conventional blasting much of the explosive energy is lost in the generation of undersize fragments or super fragmentation. The production of oversize fragments on the other hand, lowers loading and transportation efficiencies of equipment which requires secondary blasting.

Melnikov and Marchenko (1971) reported that, by introducing one or more air gaps in the explosive column, a secondary shock wave can inexpensively be generated thereby increasing the duration of the shock wave action on the surrounding rock mass by a factor of 2-5. Explosive costs were reported to be reduced by between 10% to 30% with benefits on both fragmentation and movement. Fourney et al in 1981 conducted further studies with Plexiglass blocks and supported the above findings.

DEVELOPMENT OF SANWEI Gas Bag

When bore holes are drilled for explosives to be charged into underground geological structures, it is important that the explosives be placed at predetermined levels in the borehole. To establish these levels or decks as they are commonly known, SANWEI Gas Bag evolved from products such as Plastic Spacer Pipes, Wooden discs, Floating Polyester Resin and Co-Reagents actuated plastic inflatable Decks.

However, when the temperature of the reactants in the Co-reagent type airbags varied, so did the rate of expansion, leading to difficult and unreliable use. With the introduction of aerosol activated airbags these difficulties were substantially overcome. But the bags remained simple decks with no additional qualities relating to blasting.

In particular it was found that all airbags could not resist initial blasting temperatures or the effect of detonating cords in blast holes. The effective blast holding properties of the robust woven outer layer containing the expanded airbag was discovered during extensive tests done to try and find a stemming plug for Coal and Soft Sensitive ore formations. At the same time the improved inflating properties of the non flammable gas mixtures was introduced.

So we developed the latest air decking solution SANWEI Gas Bag.

-

Product Part Blast Hole Diameter Box Qty From To BHD 76/ 89 76 mm 89 mm 40 BHD102/127 102 mm 127 mm 40 BHD140/171 140 mm 171 mm 40 BHD200/250 200 mm 251 mm 30 BHD270/311 270 mm 311 mm 20 -

SANWEI Gas Bag Applications

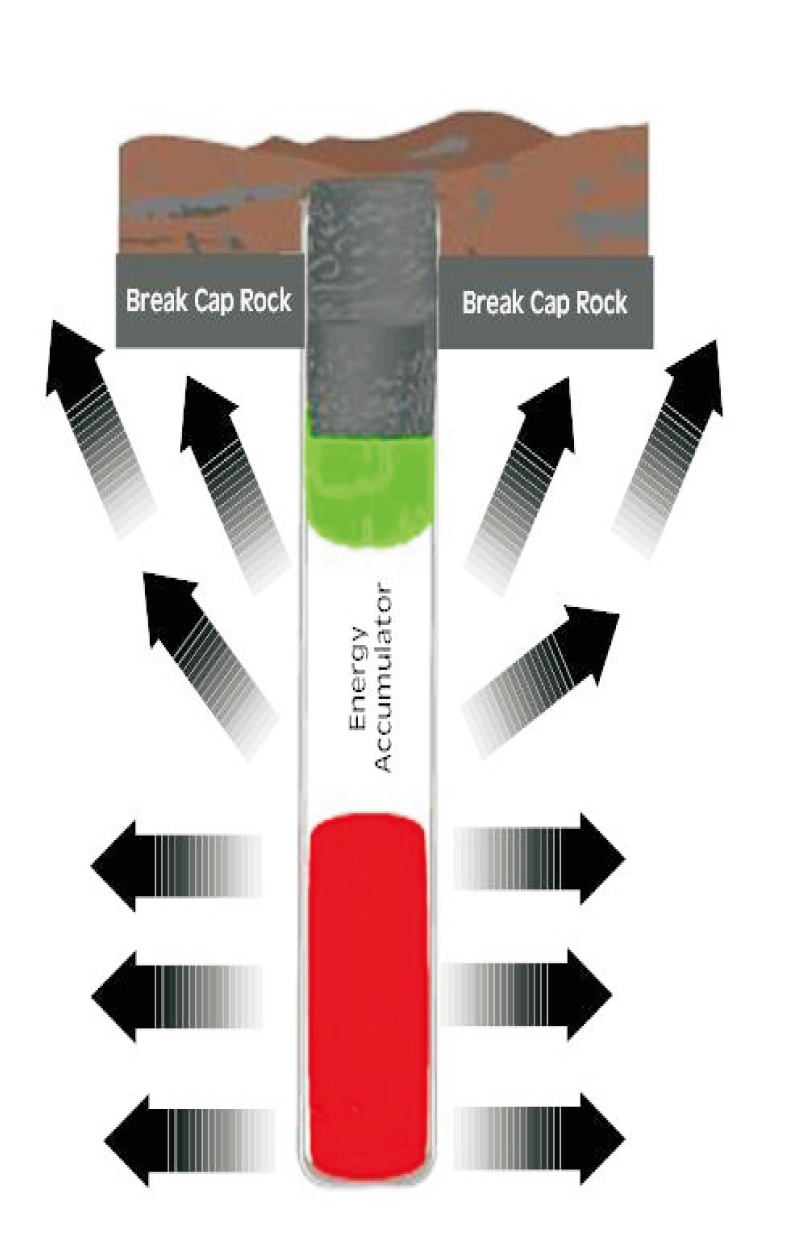

Hard cap formation

SANWEI gasbag serve as a stemming enhancer where it locks and prevents energy and gases from escaping out the top of the hole. The energy that would otherwise have been lost, is directed into the material being blasted. The energy being utilized more efficiently is great for breaking hard cap rock formation

Other uses of SANWEI Gas Bag

Pre-splitting

APPLY IN WET HOLES

SANWEI gas bag are fitted with water attachments and can easily be installed into wet blast holes, with the use of a ramrod obtainable from all SANWEI gasbag distributors.

Affix the plastic water attachment pipe, fitted to the airbag, into the female tapered cavity of the ramrod and secure with rubber band tag.

Actuate the aerosol inflator can as per a dry hole, with the ramrod leaning over the right shoulder. Lower the gasbag down the blast hole to the required depth, marked on the ramrod with some tape or twine.

Pause until the distinct sound of the retention sleeve around the gasbag bursting can be heard, to allow the gasbag to secure in the blast hole.

Ensure that the airbag is secure before extracting the ramrod and breaking the rubber band tag.

-

NEW FUNCTIONS

● Gas bag with one drop string and craft stick.

● We can customize the drop string which with printed meters onside that for improving the drill and blast efficiency.

● There are dual inflating speeds for your choosing:

Ordinary speed- Activate and lower gasbag as removed from box packing. Apply for normal temperatures( above 5℃ )

Fast speed- Slide outer bag halfway down gasbag assembly by pulling tag with one hand while holding bottom of outer with other hand. With top half of gasbag,active and lower gasbag. Apply in very cold weather temperature below 5℃ only.Also we suggest to store the gasbag in room with air condition before using in colder weather.

EQUIPMENT REQUIRED

● Lowering cord/measuring tape.● SANWEI gasbag.

● PPE

INSTRUCTIONS FOR USE

● Select the correct model of SANWEI gas bag for intended blast hole. Remove gas bag from box prior to use. Do not leave bags exposed on site to direct sunlight.

● Determine depth measurement to which bag must be lowered.

● Connect lowering cord to yellow cloth tape tag attached to the woven sleeve outer of the SANWEI gasbag.

● Holding the bag firmly with one hand,activate the aerosol using your thumb finger by pressing down on the aerosol actuator lever firmly until it latches and gas begins to spray from the aerosol.

● The bag will immediately begin to inflate after actuating the aerosol canister. Once inflation begins, it cannot be stopped.

● As fast as possible, lower the SANWEI gasbag down to depth you determined.

● Once correct depth is reached, hold the bag in position. About 20-30 seconds after actuating the aerosol, the expansion- retaining wrap will rupture allowing the bag to fully expand and grip the sidewalls of the blast hole.

● Tugging lightly on the lowering cord will confirm when the SANWEI gasbag has gripped in position.

● Use a firm upward pull on the lowering cord to break the yellow tag and detach the lowering cord from gasbag.

● For the best results in all ground types, wait about 15 minutes before loading explosives on a normal day and 30 minutes if the weather temperature below 59F(15C). If muddy borehole, it is better to use two SANWEI gas bag to increase wall contact and avoid the chance of slippage.

● Always kick in at least 2 boots of drill cuttings prior to loading a decked bag, that to protect bag from falling stemming and larger or sharp debris.

NEED ASSISTANCE WITH PRODUCTS OR SERVICES?

PLEASE SEND US YOUR ENQUIRY ...